Digitalization

Every SCIO battery has a "Digital Twin" which digitally mirrors every produced battery. This allows the battery to be tracked, maintained and updated from production through its lifecycle to recycling in a 360° process. This means an individual assessment of the performance of each module and each system. The "Digital Battery" enables data processing in a secure SCIO Cloud (in Germany) to realize condition assessment, performance prediction and lifetime optimization, i.e. with over-the-air updates and apps. This benefits manufacturers, customers and the environment, as it optimizes the use of the batteries.

Digital Battery

Thanks to the "digital Twin", the lifetime of the SCIO battery is maximized and finds a 2nd life application such as storage. When the battery has reached its end of life, the individual parts of the battery are professionally recycled.

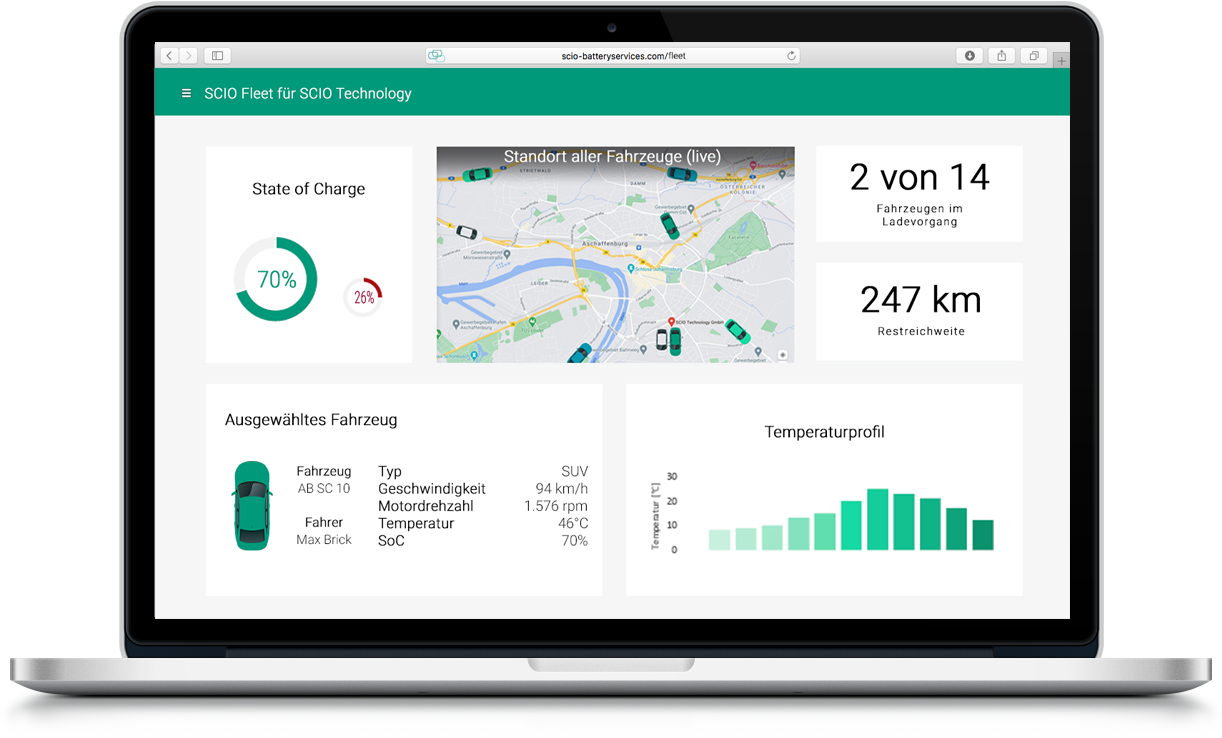

Data analysis

Simulations

Predictive maintenance

Real-time monitoring

Services